With the rise of digitalization in dentistry, intraoral scanners and digital impressions have been widely adopted by many clinicians. Intraoral scanners are used for capturing the direct optical impressions of patients’ teeth. They project a light source onto the dental arch and the images will be captured by imaging sensors that are processed by the scanning software, which generates point clouds. These point clouds are then being processed and create a 3D surface model. The trend of increasing use of intraoral scanners in dentists' daily routine has led to the need to properly assess the data quality of intraoral digital impressions.

However, measuring the quality of the 3D surface model is not as easy as simply looking it over, because sometimes a good-looking model does not equal a good quality of scan data. It may be distorted during the process and the computer then smooths everything out, which makes you feel like you captured everything, but the truth is that you are missing some critical details that will end up in a poorly fitting restoration. The blog is to teach you how to evaluate the data quality of digital impressions in basic aspects.

Data Accuracy

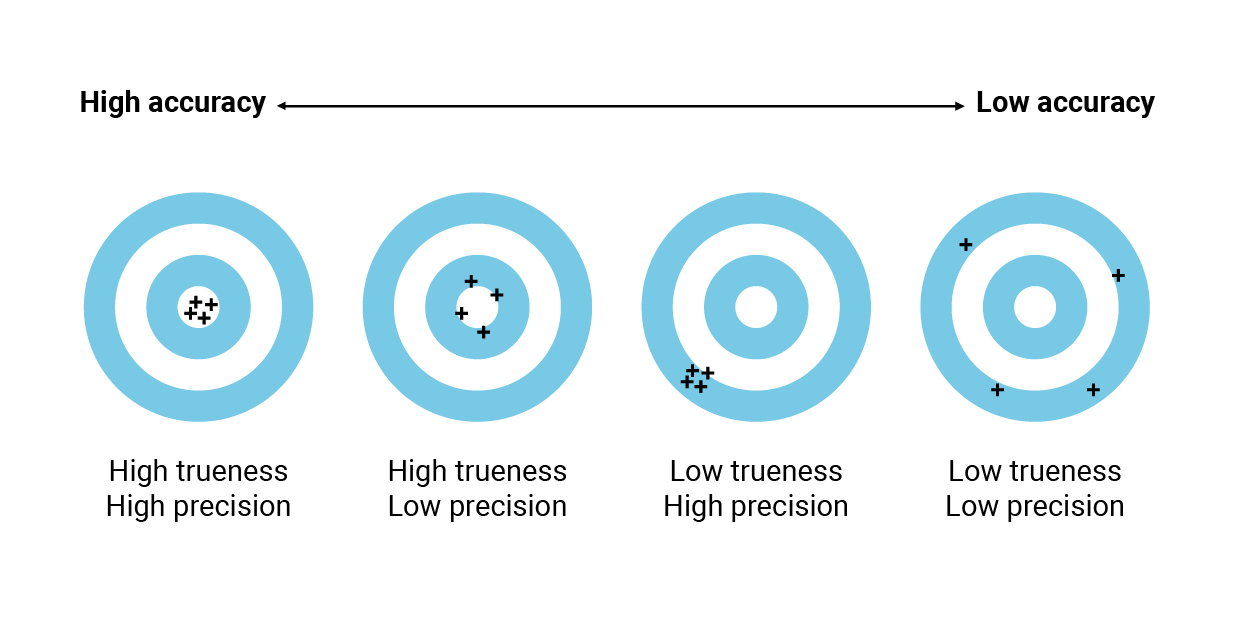

Nothing is more important than accuracy, an intraoral scanner should first have the ability to create an accurate digital impression. We need to know that accuracy is the sum of trueness and precision. Trueness is defined as the ‘closeness of agreement between the expectation of a test result or a measurement result and a true value’. Precision is defined as the ‘closeness of agreement between indications or measured quantity values obtained by replicate measurements on the same objects under specified conditions’. Simply put, trueness is the ability of a measurement to match the actual value of the quantity being measured. Precision is the ability of a measurement to be consistently repeated.

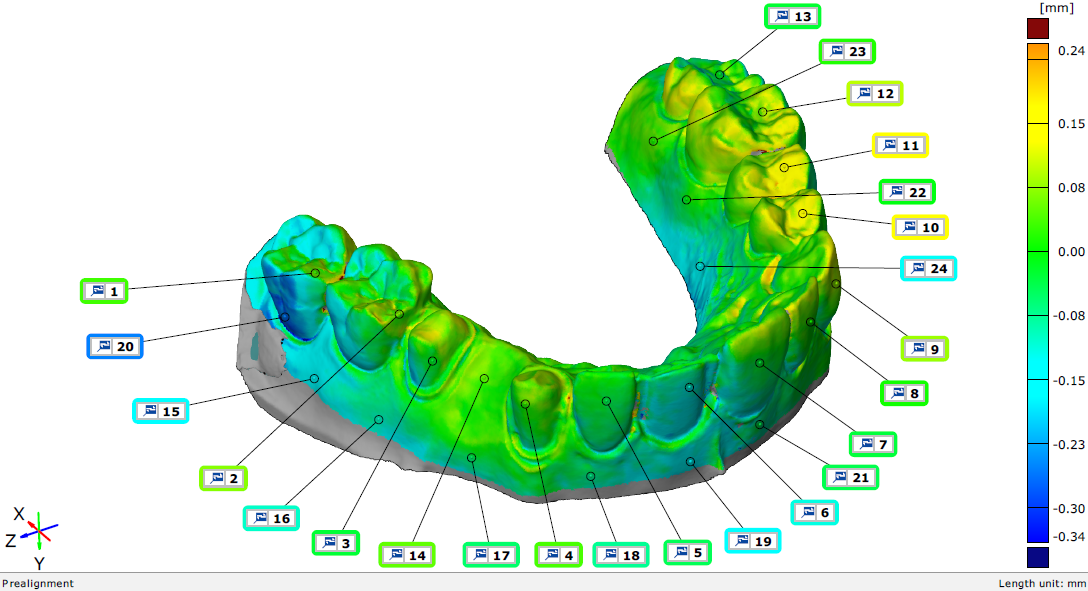

An intraoral scanner should have high trueness and that means it should be able to match reality as closely as possible: the virtual 3D model captured by the scanner should resemble the actual model as closely as possible, with minimal deviation from reality. Generally, the means of evaluating the trueness of an IOS is to overlap its scans with a reference scan obtained with a powerful industrial machine. After the overlapping of these models, powerful reverse-engineering software can be used to generate colorimetric maps displaying the differences between the surfaces of the IOS and the reference model at the micron level. To calculate precision, simply by overlapping different models taken with the same intraoral scanner at different times and again evaluating the differences at the micron level.

On this graph, you can observe the accuracy data of an impression, with different colors representing the deviation from the actual model.

It is worth noting that an IOS can have high trueness but low precision, or vice versa. In both cases, the digital impression is unsatisfactory because it would affect the overall accuracy thus will have a negative impact on the dentist's prosthetic work.

For short-span restorations(such as single-tooth restoration or fixed partial prostheses), we may not care about one-micron of error because it’s clinically insignificant. However, when it comes to long-span restorations, it will accumulate these clinically insignificant errors again and again and again, so at some point the total amount of errors that you've been accumulating might become clinically significant.

Ideally, choosing a high-accuracy scanner is a recommended choice, but it often comes with a high price. You should choose a scanner based on your budget and your need, as long as the scanner is within clinically acceptable accuracy.

Data Sharpness

Without experimental data from a professional evaluation agency/trusted third party, or your personal experience with the intraoral scanner, you cannot tell whether the data is accurate just from the digital impression alone. Let's look at the aspects of data quality that you can observe.

1. Gingival margin sharpness

When you get digital impression data from an IOS and export it into 3D image software for viewing, the first thing you can do is to judge the sharpness of the gingival margin. Margin line is a key point for dental technicians to make tooth dentures. A good digital impression must have a clear margin line so that the restorations can be made accurately. If the margin line is indistinct, it will ultimately affect the trueness of the digital impressions and the quality of the final restoration and lead to fitting failure.

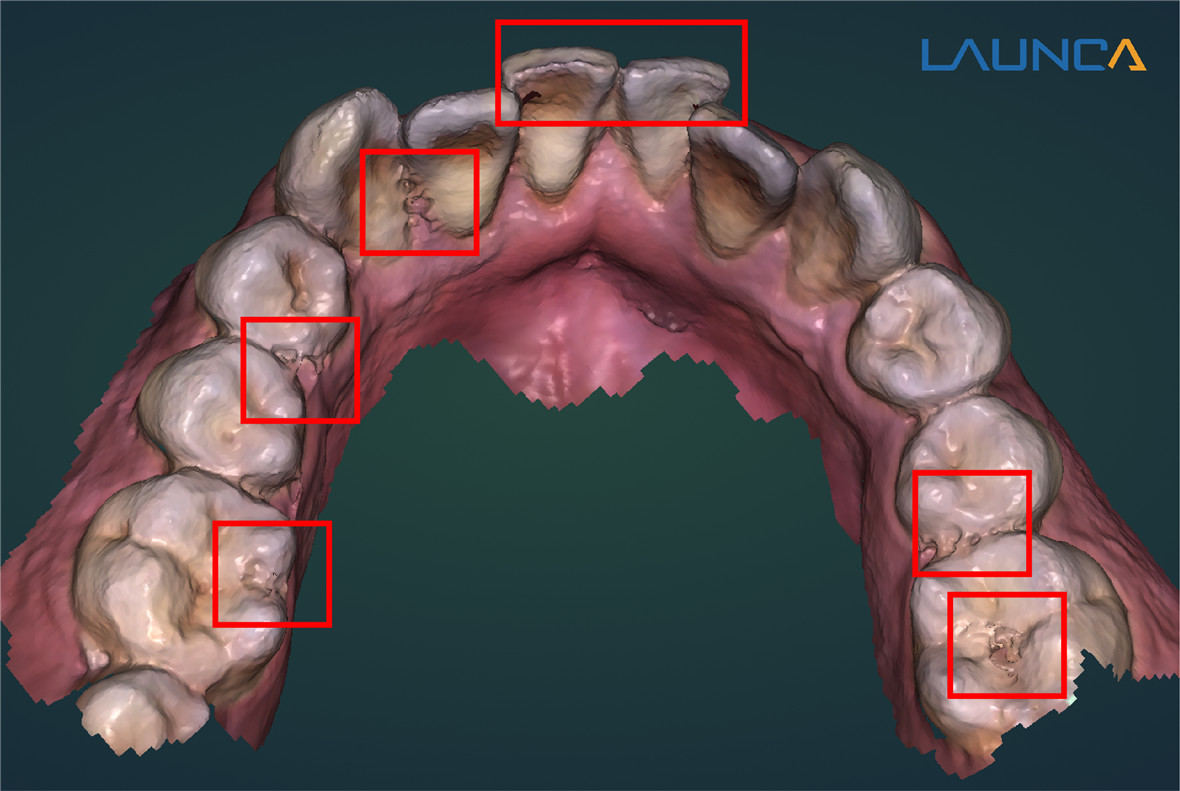

2. Distortions

You need to look carefully at the data to see if it is visibly distorted or has empty holes, which can be caused by reflections from liquids, such as saliva. This is because IOS cannot distinguish between that kind of reflection and the rest of the image it’s capturing. Keep in mind to dry up the area, and the distorted/missing data needs to be rescanned. If the operator's scanning strategy is correct and there is no refraction of other liquids and distortions still occur frequently, then the intraoral scanner is unreliable and not suitable for clinical use.

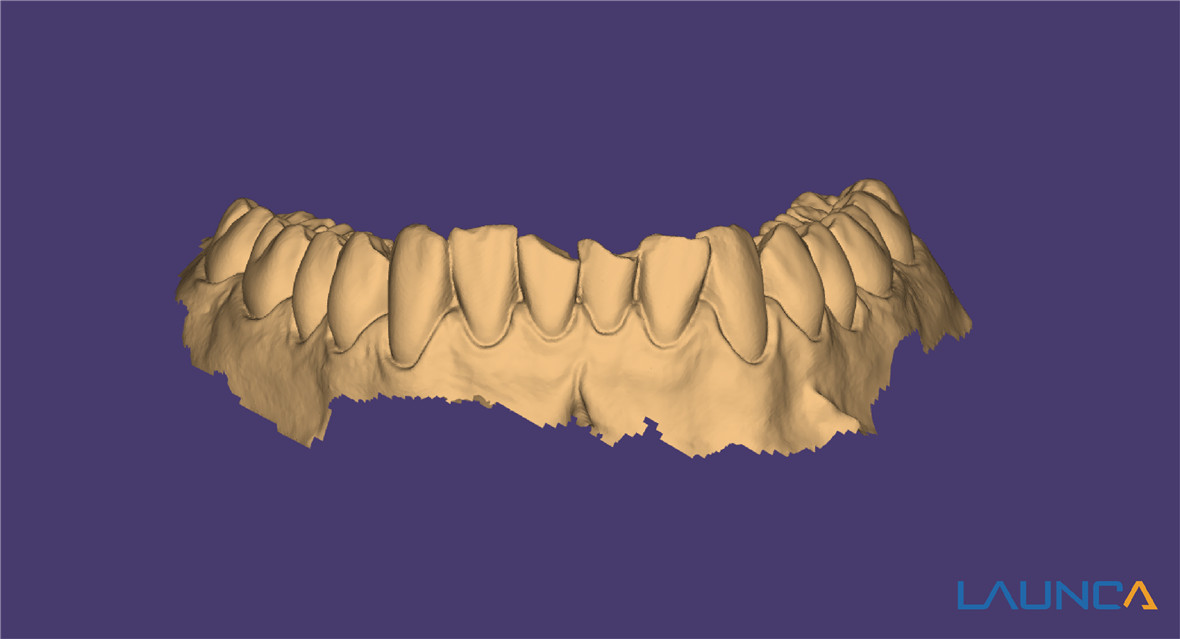

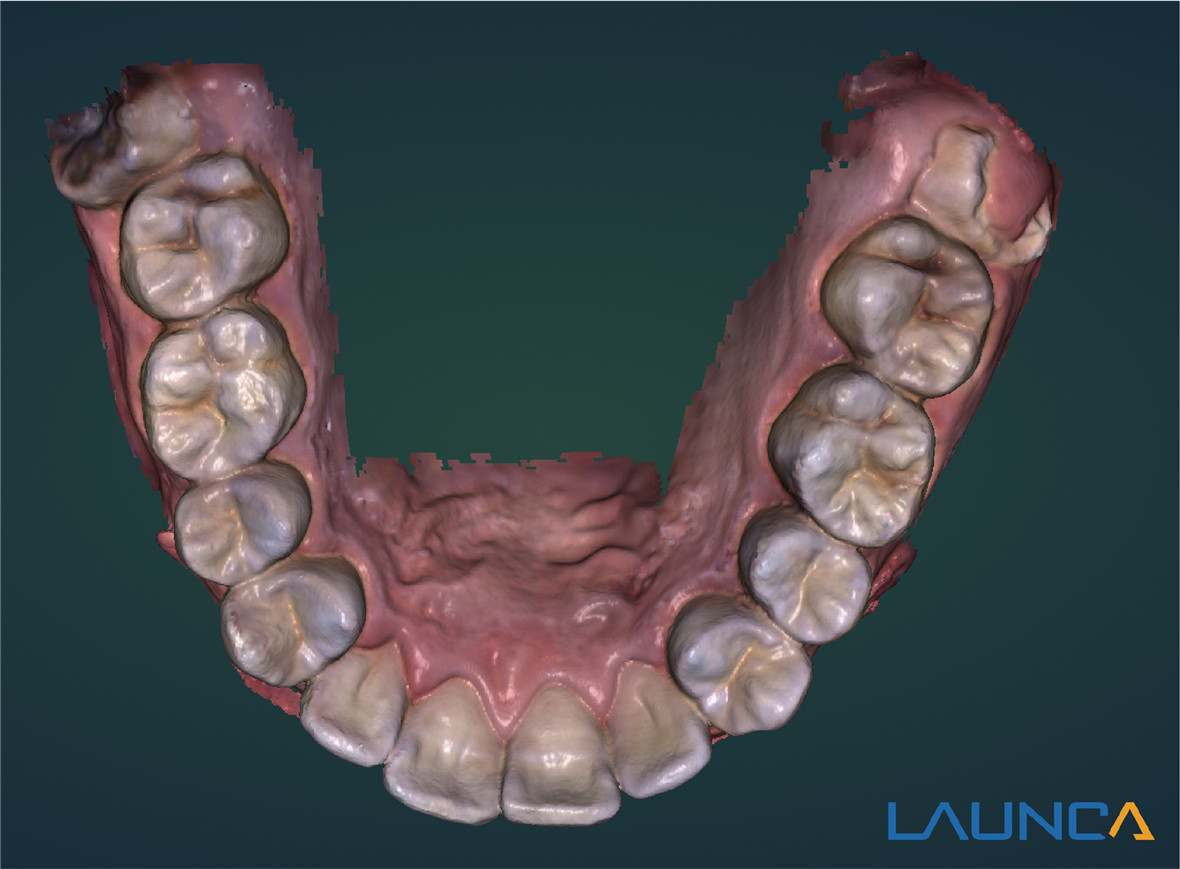

3. Occlusal surface details

Just simply observe the occlusal surfaces on the image, a good-quality digital impression data will show detailed pits and fissures.

Data Color

The color trueness and resolution of the acquisition data are also important, however, it depends on the cameras inside the scanner and the software. A powerful camera & software can generate a high-resolution realistic color 3D model and this can be a powerful marketing tool for your practice, as patients would like to see their virtual teeth model as real as possible. So when you finish the scan, comparing the data with the patient's original teeth, an image that is close to the color of the real teeth is of high quality.

Discover more about Launca DL-206 intraoral scanner: https://www.launcadental.com/intraoral-scanner

Post time: Nov-30-2021